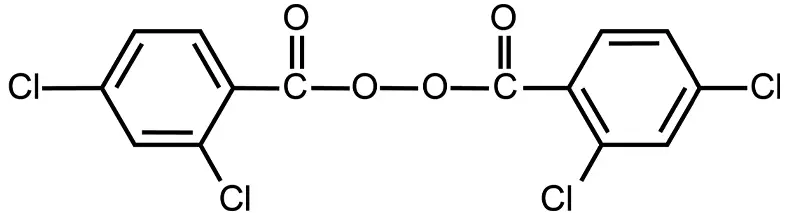

Consisting of approx. 50% di(2,4-dichlorobenzoyl)peroxide, desensitised with silicone oil.

| Nombre Químico | |||

| Di(2,4-Dichlorobenzoyl) Peroxide | |||

| Density (@20°C) | Appearance | Color | Active Oxygen Content |

| 1,2 ± 0,05 gr/cm3 | Paste form | White | 2,06 - 2,19 % |

| Peroxide Content | SADT | CAS No | EINECS/ELINCS No |

| 49,0 - 52,0 % | 60°C | 133-14-2 | 205-094-9 |

| UN No | |||

| 3106 | |||

| CARACTERÍSTICAS | |||

|

Application: This halogenated diaroyl peroxide is used as an initiator (radical source) in the crosslinking of polymers at above 100°C, particularly silicone rubbers. At below 60°C no premature crosslinking (scorch) occurs. Usage & Amount: Recommended to use 1-2 % of product as supplied on the material to be crosslinked. The paste form facilitates mixing and homogenisation. Special advantage: Crosslinking is not inhibited by oxygen. Disadvantage: sensitive to carbon blacks, possible generation of polychlorinated biphenyls (PCB's) during crosslinking process. Crosslinking of silicone rubber can be effected in the temperature range 110-130°C under pressure. Subsequent postcuring for 12-24 hours at 150-250°C removes acidic decomposition products and improves ageing resistance. Crosslinking at atmospheric pressure in continuous systems with hot air at temperatures from 150-400°C is also possible. |

|||

En AKPA Kimya Ambalaj Sanayi ve Ticaret A.Ş., damos la máxima importancia a la seguridad de sus datos personales. Con esta conciencia, nos comprometemos a procesar y preservar todos los datos personales de las personas relacionadas con la empresa, incluidos aquellos que utilizan nuestros productos y servicios, de acuerdo con la Ley de Protección de Datos Personales No. 6698 ("Ley de AEPD") de manera legal y segura. Como Responsable de Datos, procesamos sus datos personales dentro de los límites establecidos por la legislación, con plena conciencia de esta responsabilidad.

La privacidad de su vida personal y la protección de sus derechos y libertades fundamentales son nuestros principios básicos durante el uso de sus datos personales en nuestros servicios.

Propósitos y bases legales del procesamiento de sus datos personales:

Dentro del marco de las leyes y regulaciones pertinentes en los que opera nuestra empresa, utilizamos sus datos personales, como su información de identidad, dirección, número de teléfono, número de impuestos y otros datos calificados como datos personales dentro del ámbito de la Ley de AEPD, para proporcionarle servicios, realizar nuestras operaciones y actividades, identificar a las partes involucradas en cualquier transacción, registrar información y documentos necesarios para operaciones en papel o electrónicas, cumplir con las obligaciones de almacenamiento, presentación de informes y notificación a todas las autoridades competentes tanto administrativas como judiciales, llevar a cabo nuestros servicios dentro del marco de las leyes aplicables, y ofrecer otros servicios solicitados por nuestra empresa.

De acuerdo con el segundo párrafo del artículo 5 de la Ley de AEPD, el procesamiento de datos personales sin el consentimiento expreso del sujeto de datos es posible si se cumplen las siguientes condiciones:

1. Cuando esté expresamente previsto en la ley.

2. Cuando sea necesario para proteger la vida o la integridad física del sujeto de datos o de otra persona, y sea imposible obtener el consentimiento debido a la incapacidad física o legal de la persona en cuestión.

3. Cuando sea necesario para la ejecución o cumplimiento de un contrato del que el sujeto de datos sea parte o esté directamente relacionado con él.

4. Cuando sea necesario para que el responsable de los datos cumpla con sus obligaciones legales.

5. Cuando los datos sean públicos y revelados por el sujeto de datos.

6. Cuando sea necesario para el establecimiento, ejercicio o defensa de un derecho.

7. Cuando sea necesario para los intereses legítimos del responsable de los datos, siempre que no se perjudiquen los derechos y libertades fundamentales del sujeto de datos.

Transferencia de sus datos personales:

Sin el consentimiento explícito del sujeto de datos, los datos personales pueden ser transferidos a terceros por nuestra empresa si se cumplen una o más de las siguientes condiciones:

1. Cuando la transferencia de datos esté expresamente prevista en la ley.

2. Cuando la transferencia de datos por parte de la empresa sea necesaria para el establecimiento o ejecución de un contrato en el que el sujeto de datos sea parte o esté directamente relacionado.

3. Cuando la transferencia de datos sea necesaria para que nuestra empresa cumpla con sus obligaciones legales.

4. Cuando los datos personales sean públicos y se transfieran con el propósito de publicidad, siempre que se limite a este propósito.

5. Cuando la transferencia de datos sea necesaria para el establecimiento, ejercicio o defensa de un derecho.

6. Cuando sea necesario para los intereses legítimos de nuestra empresa, siempre que no se perjudiquen los derechos y libertades fundamentales del sujeto de datos.

7. Cuando sea necesario para proteger la vida o la integridad física del sujeto de datos o de otra persona, y sea imposible obtener el consentimiento debido a la incapacidad física o legal de la persona en cuestión.

Además de lo anterior, sus datos personales pueden ser transferidos a países extranjeros designados como "Países con Protección Suficiente" por la Junta de acuerdo con cualquiera de las condiciones anteriores. En ausencia de protección adecuada, los datos personales pueden transferirse a países extranjeros donde los responsables de datos en Turquía y en el país extranjero respectivo hayan garantizado por escrito una protección adecuada y se haya obtenido el permiso de la Junta.

Eliminación, destrucción o anonimización de datos personales:

a. Si bien los datos personales se han procesado de acuerdo con esta Ley y otras leyes relevantes, si las razones para el procesamiento ya no son válidas, los datos personales serán eliminados, destruidos o anonimizados de oficio por el responsable de los datos o a solicitud del sujeto de datos.

b. Se aplican las disposiciones sobre eliminación, destrucción o anonimización de datos personales establecidas en otras leyes.

c. Los procedimientos y principios para la eliminación, destrucción o anonimización de datos personales se regulan mediante reglamentos.

Sus derechos según el artículo 11 de la Ley:

Puede ejercer los siguientes derechos respecto a sus datos personales a través de una solicitud a nuestra empresa:

1. Aprender si sus datos personales han sido procesados.

2. Solicitar información si se han procesado.

3. Aprender el propósito del procesamiento y si se utiliza de acuerdo con su propósito.

4. Conocer a los terceros nacionales/extranjeros a los que se transfieren sus datos personales.

5. Solicitar la corrección si los datos personales están incompletos/incorrectos.

6. Solicitar la eliminación/anonimización de sus datos personales de acuerdo con las condiciones establecidas en el artículo de la Ley de AEPD sobre la eliminación de datos personales.

7. Solicitar que se notifique a los terceros a los que se transfirieron sus datos personales sobre las operaciones realizadas según los puntos (5) y (6) anteriores.

8. Oponerse a la obtención de un resultado en su contra debido al análisis exclusivamente automatizado de sus datos personales.

9. Si sus datos personales se procesan ilegalmente y esto le causa daño, puede solicitar la compensación de su daño.

Responsable de datos al que puede dirigirse en virtud de la Ley:

INFORMACIÓN DE CONTACTO

AKPA Kimya Ambalaj Sanayi ve Ticaret A.Ş.

Enlace de contacto: www.akpakimya.com

Yenibosna Centro Barrio Ladin Calle No:36/70 Townofis Planta:12 34197 Bahcelievler, Estambul, Turquía

Teléfono : +90(212) 580 55 59

Correo electrónico : [email protected]

Lütfen, belgeyi indirmek için formu doldurun

En kısa sürede belge mail olarak tarafınıza iletilecektir

Buscar